Your Cart is Empty

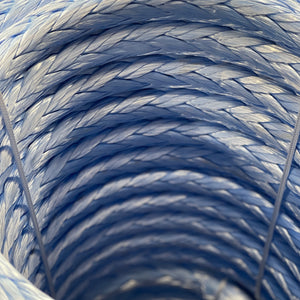

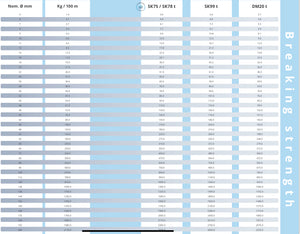

12-Strand Dyneema® SK78 / SK99 / DM20 (100m)

$0.00

The 12 strand UHMWPE/HMPE (Dyneema® SK78, SK99, DM20)construction is used to ensure that the maximum strength is delivered through the rope providing a high diameter for breaking load ratio.

Dyneema is a UHMPE (Ultra High Modulus Polyethylene, also known as UHMWPE or Ultra High Molecular Weight Polyethylene) and is available in a number of different grades.

All grades of Dyneema have excellent fatigue resistance (cyclic bending) and UV, chemical and abrasion resistance, but all have poor heat resistance due to a relatively low melting point (140 deg.C).

Dyneema offers by far the best strength to weight ratio of any material used in rope manufacture and is the material of choice for high performance cores.

100% Dyneema® delivers ultimate strength for diameter.

The rope solutions are treated with a unique coating that ensures shape stability and increased abrasion resistance to achieve a longer product life cycle. They are heated under tension to ensure maximum strength, durability and uniformity.

Our manufacturing partners in Europe are well positioned and skilled to handle unique and custom-made products according to technical drawings. The systematic manufacturing processes and checklists ensure a uniform and premium manufacturing. Before shipment ropes, slings as well as tethers have to pass the final quality inspection.

We offer a range of Dyneema / European made HMPE cores and jacketed ropes to suit application preferences as well as budget.

Features & Benefits

|

Typical Applications

|